PART-7

CHAPTER 3

METAL JOINING AND CUTTING PROCESS

Notes:

1. AW:

Arc Welding, RW: Resistance welding, OFW: Oxyfuel Gas Welding, SSW: Solid State

Welding, Soldering, Brazing

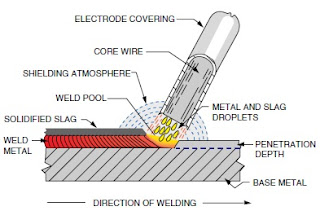

SMAW:

2. The

electrode coating in the SMAW electrode serves the following purposes.

a.

Shielding

b. Deoxidation

c.

Alloying

d.

Ionizing

e.

Insulating

3.

Heavier slag will produce beads that are smooth and have a good appearance.

4. Thin

slag will produce deposits that have rougher surfaces.

5. In SMAW, the metal droplets are transferred

across the arc by a magnetic pinch effect.

6. SMAW

electrode identification system

7. ‘E’

means electrode followed by four or five digits.

8. The

first two or three numbers refer to the minimum tensile strength of the

deposited weld metal.

Eg:

E7018; means the tensile strength of the deposited weld metal is atleast

70,000psi. E12018; means the tensile strength of the deposited weld metal is

atleast 120000psi.

9. The

next number refers to the position in which the electrode can be used.

“1” indicates the electrode is suitable for

use in any position.

“2”

indicates the electrode is suitable for use in flat position.

“4”

indicates the electrode is suitable for welding in a downhill progress.

“3” is

no longer used as a designation.

10. The

last number in the designation describes other characteristics which are

determined by the composition of the coating present on the electrode.

11. The

electrode designations ending with “5”, “6” or “8” are classified as low

hydrogen types.

12. The

below table is to be remembered.

|

F-No

|

Classification

|

Covering

& Slag

|

|

F-3

|

EXX10

|

Cellulose-Sodium

|

|

F-3

|

EXXX1

|

Cellulose-Potassium

|

|

F-2

|

EXXX2

|

Rutile-Sodium

|

|

F-2

|

EXXX3

|

Rutile-Potassium

|

|

F-2

|

EXXX4

|

Rutile-Iron

Powder

|

|

F-4

|

EXXX5

|

Low

Hydrogen-Sodium

|

|

F-4

|

EXXX6

|

Low Hydrogen-Potassium

|

|

F-4

|

EXXX8

|

Low

Hydrogen-Iron Powder

|

13. Low

hydrogen electrodes (Low moisture content-less than 0.2%) are to be stored at a

minimum oven temperature of 120 Deg C (250 Deg F)

14. The

power source for shielded metal arc welding machine is of constant current

power source, having “drooping” characteristics.

15. In

SMAW, long arc length will result in more heat produced than a short arc

length.

16.

Extremely long arc length will cause a loss of heat in the weld pool due to

loss of arc concentration, which will also result in a loss of arc stability

and weld pool shielding gases.

17. Completely

understand the picture of SMAW. The key words to identify SMAW are Electrode

Covering, Core Wire and Soldified Slag

18. Volt-Ampere

Curve for constant current power source

19. Arc

blow causes porosity and arc wandering.

20. The

reason for arc blow is the development of magnetic field around the electrode.

20. To

reduce arc blow, some of the techniques adopted are,

a. keep

the arc as short as possible.

b.

Change from DC to AC

c.

Reduce welding current

d. Use a

backstep technique

21. SMAW

is a manual process

22.

“Long Arcing” is especially likely when using low hydrogen electrodes.

23. SMAW

uses power sources such as

a.

Transformer-Rectifier

b.

Inverter power supply

c.

Gasoline or diesel engine-driven

24. The

Gasoline or diesel engine driven welding machines can be used at locations

where there is no electrical power supply

25. When

a welder increases arc length, the resistance in the welding circuit increases

due to the larger gap the current must cross. This increase in resistance

causes a slight decrease in the current flow across the arc gap. This decrease

in current results in a significant increase in voltage supplied by the power

source, which limits the drop in current.

---will continue on next blog---

These are the important points of this chapter. This blog will be updated time to time to add or delete points depends on their importance felt to the author.

This is not an official blog of AWS. The recommended reading materials as per BOK are to be read throughly before taking the exam. The exam pattern and other details to be confirmed from AWS before taking the exam.

Disclaimer: Photos are taken from different websites. If this violates any copyright rules this will be removed. Please inform me if any of the photos or contents violates copyright rules. (through 13hareesh13@gmail.com). This blog is meant for educational purpose only. If it is used for any other means without the written consent from the author, the author will not be responsible. Author does not guarantee the accuracy of data used in this blog.All the information, data, photo/image, calculations presented in this blog should be used at the sole risk of the user. The blogger is not liable or responsible in any way for any damage, losses or costs arising from use of the blog for any purpose whatsoever or whosoever it may be.

Comments

Post a Comment